SMALL ANIMAL FEED PRODUCTION LINE

Including Feed Machinery , Steel Structure ,Electric Control , Delivery, Installation and Commissioning

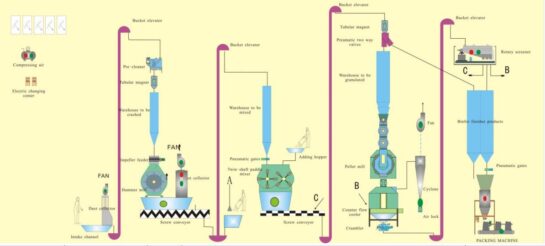

GM25E/32E Flow Chart

100.Raw material intaking

200.Grinding System – Mixing System

300.Pelleting

400.Cooling&Sifting

GM32D/35D Flow Chart

100.Raw material intaking

200.Grinding System – Mixing System

300.Pelleting& Cooling System –

400.Crumbler -Sifting

Packing System

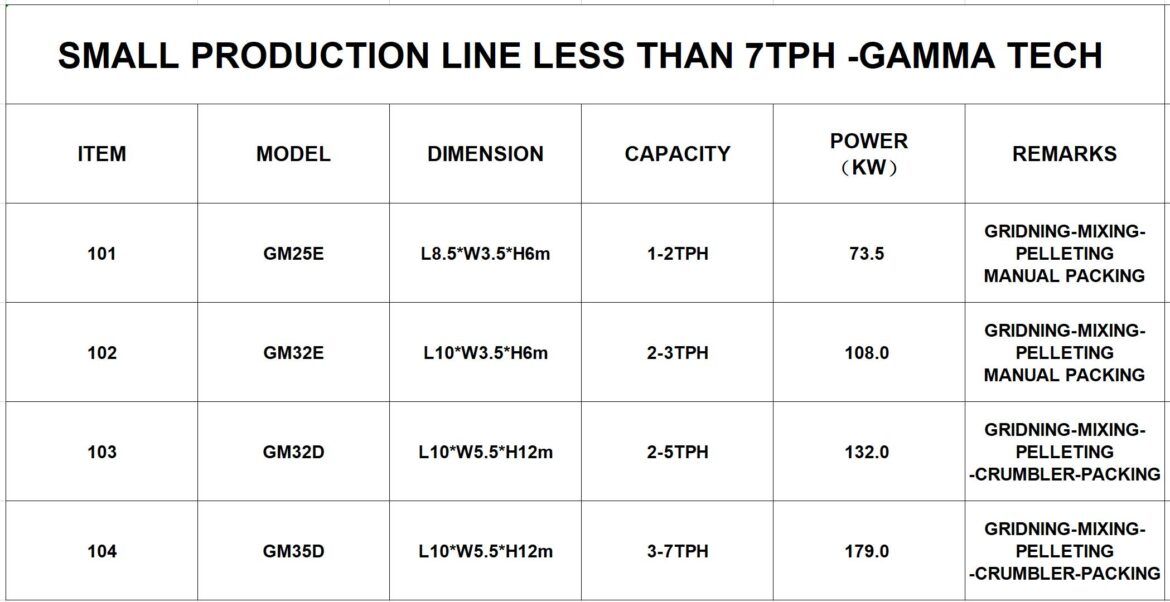

SMALL PRODUCTION LINE LIST

We have above four types of small feed prodcution line. you can choose as per your detailed inquiry . our advatage as below ;

- We are using elevators instead of screw conveyor which is fast speed and frequent maintainance

- Process is continous production which no need to stop machines during production

- Main Pellet mill for small production line we use belt type pellet mills – photos will be attached below

- Above Process we don’t have computerized dosing system .

- we can supply full turnkey project including machinery . steel platform . electric control . auxiliary machines Like Air compressor & Steam boiler etc.

- we can send engineer for supervisor to support installation and commissioning .

- D Series investment are bigger than E types . D series can supply crumbler feed and finished product packing scale included

Belt Driving Pellet Mills Model List as below :

GM25 Die Diameter 250mm Power: 0.75+1.1+22KW Capacity 1-1.8tph @ poultry feed

GM32 Die Diameter 320mm Power: 0.75+2.2+37KW Capacity 2-4tph @ poultry feed

GM35 Die Diameter 350mm Power: 0.75+2.2+30KW x2 Capacity 3-6tph @ poultry feed

GM40 Die Diameter 400mm Power: 0.75+3+45KW x2 Capacity 5-10tph @ poultry feed